In construction fields, concrete is one of the materials frequently used to build various structures, from houses to skyscrapers. However, knowing how to calculate the amount of concrete cubic needed for a project can be a challenge, especially for new pourers.

Errors in calculations can lead to wastage of material or shortage of concrete during casting, leading to overspending on material costs. Thus, let’s learn how to calculate cubic capacity efficiently in this article!

What Is Concrete Cubic Capacity?

It is important to note that concrete is a common construction material used in a building structure. Otherwise, concrete cubic capacity or concrete cubication is the calculation process to determine the needed concrete volume in a construction accurately.

By measuring or cubicating, contractors can determine the amount of concrete to be used in building beams, floors, and other concrete structures. The cubication process usually involves calculating the dimensions and volumes of various building elements, such as beams and floors.

Next, the result will be used to determine the number of concrete needed. That way, material procurement planning and concrete delivery schedules can be better.

Read also: How to Calculate Cement Requirements: Here’s the Guide

Why Is Calculating Concrete Cubic Capacity Important?

In building construction, concrete cubication is important to ensure that the project will run smoothly through efficient material usage and controlled construction cost. Generally, calculating concrete cubic capacity is crucial for various reasons, such as:

- Construction planning.

- Shipping of materials.

- Storage of materials.

- Determining the amount of materials, such as cement, sand, and reinforced concrete needed.

How to Calculate Concrete Cubic Capacity

Measuring the concrete cubic capacity accurately and based on the initial planning will make the construction run smoothly due to efficient execution. In determining the concrete cubication, the unit used is m3 or cubic meter. Below are some steps you must know to calculate concrete cubic capacity:

1. Understanding the Structure

The first thing to do is to understand the structure that must be measured. This is because concrete structures have different shapes, such as columns, beams, foundations, floor slabs, or other elements. Moreover, each shape has a different volume formula.

2. Determining the Dimension

After figuring out the structure, you can determine the dimension. This calculation needs good accuracy and is noted in meters (m) to get the result in cubic meters (m3).

3. Implementing the Volume Formula

The next step is implementing the formula based on the concrete structure. Below are each explanation for concrete cubication based on the structure:

A. Beam

B. Floor Slab

C. Footing Foundation

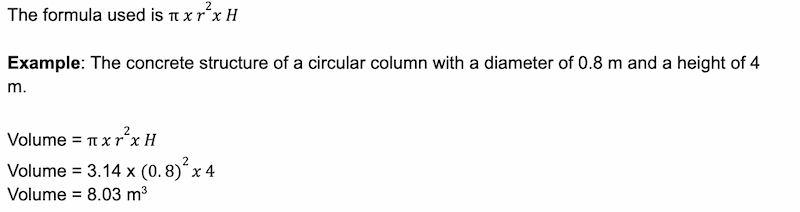

D. Cylinder

Read also: The Right Concrete Mix Ratio According to SNI Standards

4. Summing the Volume

If you have more than concrete elements with different shapes, you can calculate the volume of each shape and sum them. That way, you can get the total needs of concrete cubic capacity accurately.

5. Adding Tolerance

Lastly, it is advisable to add 5–10% of tolerance from the total volume to anticipate loss due to delivery, execution, or unexpected additional needs.

For example, if you need 20 m3 concrete, you can add 10% of tolerance by calculating as follows:

20 x 10% = 2

Concrete total: 20 + 2 = 22 m3

Example of Concrete Cubic Capacity Calculation

To make it easier to understand, let's look at the following example of concrete cubic calculation:

You will build a house with a concrete structure in the form of floor slabs and beams with the following measurements:

A. Floor Slab

Amount: 3

Dimension: Length 8 m, width 6 m, and height 0.12 m

B. Beam

Amount: 10

Dimension: Length 5 m, width 0.3 m, and height 0.4 m

First, you must calculate the total volume of each structure. Below are the formulas:

- Beam volume= 5 x 0.3 x 0.4 = 0.6 m3

- Total beam volume (10 pieces) = 0.6 x 10 = 6 m3

- Slab volume= 8 x 6 x 0.12 = 5.76 m3

- Total slab volume (3 pieces) = 5.76 x 3 = 17.28 m3

- Total concrete volume (beam + slab) = 6 + 17.28 = 23.28 m3

- Tolerance of 10% = 23.28 + 2.328 = 25.06

Thus, the total amount of concrete needed is 25.06 m3.

Those are the explanations of how to calculate concrete cubic capacity that is important to understand before starting construction. By measuring the concrete cubic capacity, you can determine the planning of building material procurement efficiently.

If you are interested in using precast concrete for construction, Precast Concrete by Semen Merah Putih can be your go-to solution. We produce various precast concrete, such as Box Culvert, Sheet Pile, Slab, Girder, U-Ditch, Barrier, pile, and other customs.

Through one of its subsidiaries, Merah Putih Beton, Semen Merah Putih supplies innovative ready-mix concrete products designed for a variety of unique and strong applications through its superior products such as Ready-Mix Concrete, Precast Concrete, and Aggregates.

Merah Putih Beton's ready-mix concrete products are made to meet customer demands for a range of uses. They come in various quality options and can be used for a number of construction projects, including commercial and industrial ones, as well as infrastructure projects like building high-rises, homes, highways, and other structures.

Contact us now to get more information about Semen Merah Putih and find the best construction solution!

Read also: How to Calculate Autoclaved Aerated Concrete Properly